Home > Products > Surface Treatment > Mechanical industry hot spray zinc surface treatment

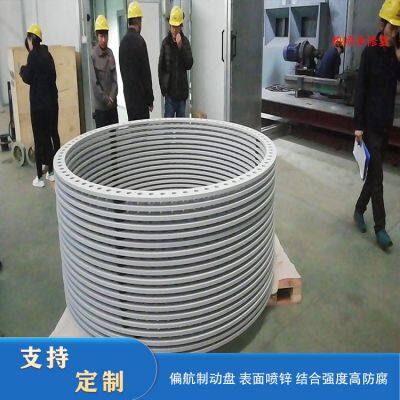

Mechanical industry hot spray zinc surface treatment

- 1000 Square Meter / Square Meters per Month

- T/T

You May Like

-

Preparation of anti-corrosion and wear-resistant tungsten carbide coating by supersonic spraying

-

Machine industry Fluidized bed Thermal spraying processing Teflon preparation anti-corrosion wear-resistant can support customized

-

Surface treatment of filter core plate using plasma technology for corrosion prevention, wear resistance, and high temperature resistance

-

Surface treatment of machinery industry Thermal spraying plasma process anti-corrosion, wear-resistant and thermal insulation

-

Surface treatment in the mechanical industry, spraying tungsten carbide for corrosion prevention and wear resistance

-

Directly supplied by the manufacturer for laser cladding surface treatment, piston rod surface repair, anti-corrosion and wear-resistant

Product Details

| Brand Name | Yaw brake disc spray repair | Place of Origin | China | |

| Model Number | customizable |

Product Description

As a key component of fan, yaw brake disc is exposed to harsh environment for a long time, facing challenges such as corrosion and wear, which directly affects fan operation efficiency and life. Zinc spraying process, as an efficient means of protection, provides strong protection for the yaw brake disc. It is a process in which zinc wire or zinc powder is heated to a molten or semi-molten state by thermal spraying technology, and is sprayed to the surface of the substrate by high-speed air flow to form a dense zinc coating. This process is widely used in the field of metal surface protection, especially in harsh environments, showing excellent performance, becoming the choice of more and more manufacturers.

Advantages of zinc spraying process:

Excellent anti-corrosion performance: Zinc layer as a sacrificial anode, preferential corrosion, effectively protect the base metal, significantly extend the service life of the brake disc.

Excellent adhesion: The zinc spray layer is firmly combined with the matrix, and is not easy to flake off, ensuring long-term protection effect.

Good wear resistance: moderate hardness of zinc layer can effectively resist wear during braking and reduce maintenance costs.

Environmental protection and high efficiency: zinc spraying process is pollution-free, and the construction efficiency is high, suitable for mass production.

Jinan Tianmeng has been deeply engaged in the field of thermal spraying for many years, and we know the importance of zinc spraying process. We use advanced zinc spraying equipment and technology to strictly control each process to ensure stable and reliable quality of zinc spraying layer. Choose Jinan Tianmeng Technology Co., LTD., you will get quality repair services and good use experience. We look forward to working with you to protect your equipment together!

Contact Us

- Jinan Tianmen New Material Technology Co., Ltd

- Contact nameXue Yunling Chat Now

Product Categories

| Surface Treatment |

New Products

-

Repair of the surface of the drying cylinder by spraying tungsten carbide+Teflon anti-corrosion and wear-resistant non stick coating

-

Surface repair of the mechanical industry, multi section roller, supersonic spraying processing, tungsten carbide coating, wear-resistant and anti-corrosion

-

Boiler surface repair and spraying of nano ceramic coating for anti-corrosion and wear prevention

-

Support customized mechanical sliding rails for laser melting surface repair, anti-corrosion and wear-resistant

-

Ceramic coating scraper, coating scraper, paper coating roller and other mechanical scraper products

-

Surface repair and aluminum spraying treatment process for mechanical valves in the source factory

-

Roller surface repair using spray welding process NI60 coating wear-resistant and anti-corrosion preparation

-

Mechanical industry supersonic spray machining spiral shaft surface repair, spraying anti-corrosion and wear-resistant coating

-

The surface repair of stainless steel plates by the manufacturer adopts arc spraying process LX88A coating, which is super hard and wear-resistant

-

Surface repair of stainless steel plates in the mechanical industry, arc spraying, wear resistance and corrosion resistance

-

Thermal spraying processing hopper surface repair Spraying tungsten carbide coating for anti-corrosion and wear resistance, with a wide range of applications

-

Thermal spraying processing hopper surface repair Arc spraying anti-corrosion and wear-resistant with a wide range of applications

-

Teflon coated coated steel products coating hardness can be adjusted packaging anti-collision

-

Arc spraying repair of GP-99 coating on the surface of Tianmeng roller with anti-corrosion and wear-resistant adjustable coating hardness

-

Metal surface treatment, thermal spraying, tungsten carbide processing, anti-corrosion and wear-resistant for Tianmeng wind cap disk

-

Tianmeng plasma spraying ceramic anti-corrosion, wear-resistant and anti-collision packaging with adjustablehardness

-

Anti corrosion construction of oil pipeline in the oil torch tower of Petro Pak Oil Company

-

Tianmeng Thermal Spray Processing Supersonic Spray Anti corrosion and Wear Resistant Coating

-

Tianmeng Hot Spray Processing Hot Spray Aluminum Process Wear resistant and Anti corrosion Surface Treatment Adjustable Hardness

-

Tianmeng Thermal Spray Processing Surface Repair Teflon Coating Processing Anti corrosion and Wear Resistance

-

Tianmeng wear-resistant sleeve thermal spraying processing supersonic spraying anti-corrosion and wear-resistant preparation

-

Preparation of anti-corrosion and wear-resistant ceramic coating by plasma spraying on the surface of Tianmeng shell

-

Heavenly Alliance Reactor Supersonic Spray Processing Anti corrosion and Wear Resistant Hard Coating Optional

-

Mirror drying cylinder spray enhanced supersonic thermal spraying tungsten carbide anti-corrosion and wear-resistant coating

Popular Searches

- water treatment

- powder coating

- cnc machining

- aluminum profile

- air tool

- air compressor

- air gun

- aluminum parts

- die casting

- Aluminum Extrusion Profile

- Cleaning Machine

- gas heater

- Shot Blasting Machine

- gas burner

- Vinyl Floor

- Food Processing

- air brush

- fluid handling

- Surface Treatment Machine

- equipment cleaner

- Metal Welding Part

- latex dipping

- burner infrared

- Black Surface Treatment

Recommended Products

- Preparation of anti-corrosion and wear-resistant tungsten carbide coating by supersonic spraying

- Dryer surface coating customization

- Thermal Spraying Arc Spraying Enhanced Roller Surface Repair

- Ceramic roller

- Custom boiler tube

- Supersonic Spray Boiler Tube

- The Teflon roller

- Scraper paper scraper ceramic coating

- The performance of boiler tube was improved by arc spraying enhanced surface wear-resistant anticorrosive coating

- Laser cladding surface modification

- Thermal spraying company gear shaft surface spraying supersonic processing tungsten carbide coating durable

- Spray tungsten carbide coating thermal spray nickel base alloy anti-corrosion and wear-resistant spray welding

Find Similar Products By Category

- Mechanical Parts & Fabrication Services > Custom Fabrication Services > Finishing

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Xue Yunling

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Xue Yunling

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile